Market for 3D-printed medical devices to cross $2 bn by 2025

March 7, 2018

Source: TechCircle

616

616

The global market for 3D printing of medical devices is estimated to touch $2.77 billion by 2015, according to a new study by market research and investment information firm Profshare Market Research.

This would translate to a compound annual growth rate (CAGR) of 16.8% between 2017 and 2025.

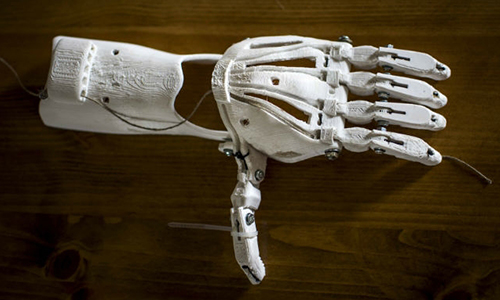

3D printing is an additive type of manufacturing, where a three-dimensional object is created by building successive layers of raw material. Every layer is attached to one another until the object is fully completed. Objects are produced through a digital 3D file, such as a computer-aided design (CAD) drawing or a Magnetic Resonance Image (MRI).

This technique can also be used to create medical devices.

"No additional setup of equipment or tools is required as 3D printing allows designers to make changes easily," Profshare said in a statement. "The flexibility of 3D printing devices allows manufacturers to create devices matched to a patient’s anatomy (patient-specific devices) or even devices with very complex internal structures."

The firm said that these capabilities have generated massive interest in 3D printing of medical devices.

Scientists are researching how to manufacture living organs such as a heart or liver using the 3D printing process, it further said.

The study classifies 3D-printed medical devices into two categories -- external wearable devices and clinical study devices.

External wearable devices are those 3-D printing devices customized to fit each patient.

"In this process, 3-D printing is usually accompanied by 3-D scanning helping to create the geometry.These devices can be attached to the outside of a person. These devices are larger or thicker than those surgical devices or implants that have to reach into a body. This actually helps to overcome any mechanical strength issues with 3-D printing," the study explained.

On the other hand, clinical study devices are created for studies where build quantities are low and design changes after evaluation are likely.

These devices often have multiple plastic components where 3D printing offers a cost-effective way to create clinically usable parts in low cost, the study said.

Another report by ResearchAndMarkets claims that the global 3D printing plastic market is expected to grow at a CAGR of 26.5% to reach $1.34 billion by 2022. It expects companies such as Stratasys, SABIC, DOW Chemicals, BASF, and 3D Systems to capitalized on this growth.

In further signs that 3D printers could spark a healthcare revolution, a recent report had suggested that the technology is now seemingly capable of manufacturing drugs.

According to a report on tech portal Motherboard, researchers created muscle relaxants and drugs to treat ulcers using 3D printers.

This potentially means that doctors could develop drugs quickly to help halt outbreaks. It also means that people could possibly make simple medicines at home.

Researchers at the University of Glasgow showcased a new process of making drugs using 3D printers worth $2,000.

By DduRead more on

- Disposable Medical Products that Keep Your Medical Facility Clean and Sterile March 31, 2022

- 10 Triumphant Drug Launches Of The Decade August 26, 2021

- Ultrasonic Nebulizer Market Views September 6, 2018

- 4 Best-Selling Digital Thermometers on Drugdu.com in 2018 September 5, 2018

- Don’t Miss These Tips before Your Cardiac Monitor Purchase September 5, 2018

your submission has already been received.

OK

Subscribe

Please enter a valid Email address!

Submit

The most relevant industry news & insight will be sent to you every two weeks.