Schott Pharmaceuticals, Corplex, and Takeda Pharmaceuticals successfully demonstrate closed-loop recycling systems

November 27, 2024

Source: drugdu

405

405

Together with Takeda Pharmaceuticals and Corplex, Schott Pharmaceuticals has successfully conducted a ton level emission reduction pilot study, improving resource utilization efficiency and reducing carbon emissions in the pharmaceutical supply chain Research has shown that closed-loop recycling of pallets used for packaging and shipping drug sealing solutions is technically and supply chain feasible. When using 70% recycled materials for pallets, greenhouse gas (GHG) emissions can be reduced by up to 50%.

Schott Pharmaceuticals, a supplier of drug packaging and delivery solutions, Corplex, a leader in transportation packaging design, manufacturing, and recycling, and Takeda Pharmaceuticals, a leading global biopharmaceutical company, are collaborating to promote circular economy solutions in the pharmaceutical industry. Three companies have collaborated to conduct a pilot study on the closed-loop recycling of disposable pallets. During drug transportation, these trays are used to hold injection bottles, syringes, and ampoules, and are currently only for disposable use. We strive to establish new standards through collaboration to help the pharmaceutical industry reduce environmental impact. By developing a tray closed-loop recycling system, we are working hard to find a solution that can improve material utilization, reduce carbon emissions, and not affect product quality or patient safety, "said Andreas Reisse, CEO of Schott Pharmaceuticals. Pilot studies have shown that disposable plastic packaging that was originally intended to be disposed of in garbage bins can be converted back into raw materials. A peer-reviewed lifecycle assessment confirms that closed-loop recycling can reduce negative environmental impacts: materials can be recycled and reused after use, and then put back into production at the same quality level. When 70% of recycled materials are used, greenhouse gas (GHG) emissions can be reduced by up to 50%. The closed-loop system can achieve high-quality polypropylene recycling at the same quality level.

The pharmaceutical industry is a strictly regulated market as all drugs, including life-saving drugs, must be safely delivered to patients. At present, the main method to avoid pollution is to use disposable products and raw materials. The same applies to intermediate packaging, such as pallets, which can be used to protect pharmaceutical containers during storage and transportation, ensuring product safety and reliability. These disposable trays are made of high-quality polypropylene, and once the drugs arrive at the pharmaceutical company, they will be discarded or downgraded for recycling. Although the requirement for high quality is a standard process in the pharmaceutical industry, it brings certain challenges when implementing the concept of "responsible consumption and production" in the United Nations Sustainable Development Goal 12. In a pilot project, Schott Pharmaceuticals, Corplex, and Takeda Pharmaceuticals jointly conducted research to explore how to organically combine the two and implement them in practice.

For nearly half a century, we have been committed to helping industrial enterprises use recycled materials in their production cycles. Currently, pharmaceutical companies have not yet achieved the use of recycled materials in production. We are pleased to explore solutions together to pave the way for the use of recycled materials in pharmaceutical packaging, "said Lucas van der Schalk, CEO of Corplex.

Three companies carefully designed and jointly conducted a large-scale experiment. Focus on optimizing the operational efficiency of reverse logistics, verifying the feasibility of recycling technology, and evaluating the impact on the environment. A total of 13 cycles of recycling were conducted in this experiment, and approximately 20 tons of waste packaging materials were transported from Takeda Pharmaceuticals and Schott Pharmaceuticals to Corplex in a clean and controllable manner. The collected materials are reprocessed into granules for the production of new pallets. At the same time as the experiment, extensive research is still being conducted in the laboratory to study the quality of particles and trays over multiple recycling cycles. The experimental results indicate that compared to trays made with native materials, trays made with closed-loop recycled materials can also meet the usage requirements.

The life cycle assessment led by the Dutch Centre for Life Cycle Assessment (LCA Centre) confirms that pallets produced using closed-loop recycled materials have more environmental advantages than pallets produced using native materials. This life cycle assessment is strictly carried out in accordance with relevant ISO standards and the recognized standard of Global Warming Potential (GWP) of the Intergovernmental Panel on Climate Change (IPCC) proposed by the United Nations. The evaluation results indicate that using 70% recycled materials for pallets can reduce greenhouse gas emissions by up to 50%.

Looking ahead to the future: From point to surface, promote the application of pilot projects in daily operations, and support the overall transformation of the industry.

Our focus is on minimizing the negative impact of our company's products and business on the environment based on the principles of circular economy. The success of the pilot study proves that we have found the right direction for reform. Next, we will work together with Schott Pharmaceuticals and Corplex to promote the results of the pilot project to daily operations, "said Johanna Jobin, Global Head of Environment and Sustainable Development at Takeda Pharmaceuticals.

The results of this joint pilot prove that closed-loop recycling can improve resource utilization efficiency and reduce emissions by up to tons. Next, we will further expand the scale of closed-loop recycling and review successful practices such as pallet size standardization. In short, involving other pharmaceutical companies and supporting the entire industry towards a more sustainable development path.

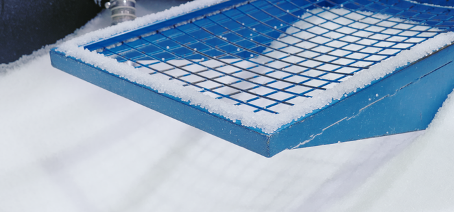

Schott Pharmaceuticals, Corplex, and Takeda Pharmaceuticals collaborate to promote circular utilization in the pharmaceutical industry. Image source: Schott Pharmaceuticals

Schott Pharmaceuticals, Corplex, and Takeda Pharmaceuticals collaborate to promote circular utilization in the pharmaceutical industry. Image source: Schott Pharmaceuticals

For safety reasons, packaging in the pharmaceutical industry is usually disposable. Schott Pharmaceuticals has collaborated with Takeda Pharmaceuticals and Corplex to achieve closed-loop recycling for the first time. Image source: Schott Pharmaceuticals

For safety reasons, packaging in the pharmaceutical industry is usually disposable. Schott Pharmaceuticals has collaborated with Takeda Pharmaceuticals and Corplex to achieve closed-loop recycling for the first time. Image source: Schott Pharmaceuticals Extract polypropylene from used trays and use it to produce new trays for packaging and transporting medication bottles or cartridges. Image: Schott Pharmaceuticals

Extract polypropylene from used trays and use it to produce new trays for packaging and transporting medication bottles or cartridges. Image: Schott Pharmaceuticals

Read more on

- Gan & Lee Pharmaceuticals’ new PROTAC drug GLR2037 tablets have been approved for clinical trials to enter the field of prostate cancer treatment March 3, 2026

- AideaPharmaceuticals plans to raise no more than 1.277 billion yuan through a private placement to focus on the global clinical development of innovative HIV drugs March 3, 2026

- Giant Exits! Its Star Business Acquired March 3, 2026

- Focusing on cardiovascular and cerebrovascular diseases! OpenMediLead Medical Intelligence Dual Engines Launch Internal Testing, Connecting Drug Development and Clinical Diagnosis in a Closed Loop March 3, 2026

- Innovent Biologics Announces Approval of New Indication for BTK Inhibitor “Pitubrutinib” in China March 3, 2026

your submission has already been received.

OK

Subscribe

Please enter a valid Email address!

Submit

The most relevant industry news & insight will be sent to you every two weeks.