From minerals to tablets

September 18, 2024

Source: drugdu

362

362

F Lab is suitable for a wide range of applications, such as feasibility studies, quality control, and troubleshooting during production. The powder analyzer can be used to check the tableting process of a formulation. Users can test raw materials under special conditions and compare various formulations. The compact device can even detect changes in the mineral mixture due to compositional changes. This powder analyzer is therefore a great support for the development of new products.

F Lab is suitable for a wide range of applications, such as feasibility studies, quality control, and troubleshooting during production. The powder analyzer can be used to check the tableting process of a formulation. Users can test raw materials under special conditions and compare various formulations. The compact device can even detect changes in the mineral mixture due to compositional changes. This powder analyzer is therefore a great support for the development of new products.

The powder analyzer can be automated and is available in two models: the F Lab 5 with a pressing force of 5 kN for tablets up to 10 mm in diameter, and the F Lab 10 with a pressing force of up to 10 kN for tablets up to 15 mm in diameter. Depending on the customer's needs, the device can be combined with an automatic data evaluation and display program and other analysis equipment.

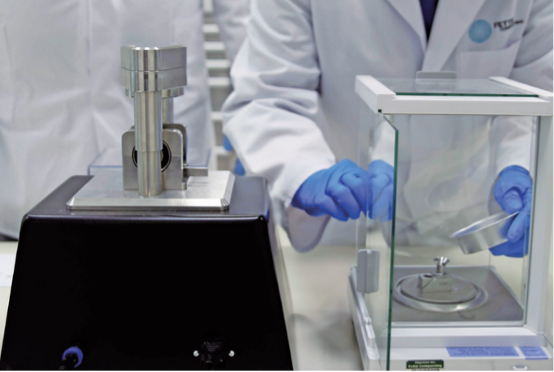

The analysis process is simple: the operator weighs the powder required for the tablets, fills the die, and starts the data analysis process via a computer program. The analysis records the tablet characteristics such as thickness, mass, diameter, and hardness. During the measurement, the computer program calculates various parameters: ejection force, breaking strength, elastic recovery, etc. The powder analyzer automatically generates visual graphs that clearly identify powder blends with better tableting properties, even for non-experts.

Customers also benefit from the easy-to-learn powder analyzer, which significantly reduces the time it takes to train operators. The automatic tableting analysis of the powder analyzer means that customers can save resources and optimize the formulation development process at an early stage of R&D. This not only helps to expand the market quickly and shorten the time to market, but also provides a deeper understanding of the product and avoids mistakes in the production process. In addition, the F Lab powder analyzer saves resources by reducing unnecessary powder waste during the testing phase. If the formulation needs to be modified, the powder analyzer can detect this before the resources are integrated into production. This not only reduces material costs but also reduces downtime of production equipment. Users can also use the device when troubleshooting.

For MAGNESIA, the difficult problem was to choose the most suitable particle for tableting from 4 different mineral particles of the same raw material. In addition, it was necessary to identify possible shortcomings of different particles and test different parameters such as pressure. MAGNESIA was able to make correct data-based decisions in product development after performing extensive and in-depth analysis with the help of the F Lab powder analyzer. The tool presents a visual analysis of which particles work best under which parameters and properties in large-scale production.

Today, the pilot project carried out by Fette in Schwarzenbeck, Germany, also helps MAGNESIA reduce the costs incurred when comparing raw material quality and suppliers. In the event of a product failure, users of the F Lab powder analyzer can quickly rule out the possibility of a defect in the product itself, which has long been the case with the F Lab series. In addition, F Lab helps companies to strengthen their understanding of their products and their characteristics, which gives them an advantage when talking to customers.

Quality by Design (QbD) means that only by fully understanding the product and the development process can high-quality products be produced. F Lab understands the powder tableting process from the outside to the inside, from the shallow to the deep, and not leaving out any details. This knowledge can be applied throughout the entire product life cycle, from development to quality control.

https://pharm.jgvogel.cn/c1442003.shtml

By editorRead more on

- Gan & Lee Pharmaceuticals’ new PROTAC drug GLR2037 tablets have been approved for clinical trials to enter the field of prostate cancer treatment March 3, 2026

- AideaPharmaceuticals plans to raise no more than 1.277 billion yuan through a private placement to focus on the global clinical development of innovative HIV drugs March 3, 2026

- Giant Exits! Its Star Business Acquired March 3, 2026

- Focusing on cardiovascular and cerebrovascular diseases! OpenMediLead Medical Intelligence Dual Engines Launch Internal Testing, Connecting Drug Development and Clinical Diagnosis in a Closed Loop March 3, 2026

- Innovent Biologics Announces Approval of New Indication for BTK Inhibitor “Pitubrutinib” in China March 3, 2026

your submission has already been received.

OK

Subscribe

Please enter a valid Email address!

Submit

The most relevant industry news & insight will be sent to you every two weeks.